Customised solutions

We - HSB Automation GmbH - is known for being able to offer its customers bespoke solutions for every application.

The right solution is available for every application from our wide range of linear modules. And if this is not the case, we modify our drives to meet the requirements. This is one of our great strengths.

Over the many years since our company was founded, we can look back on a considerable number of individually customised solutions.

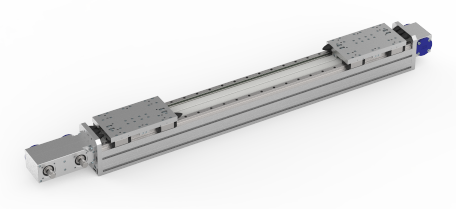

Modified standard units

This area represents the simplest of the customised solutions: standard units are optimised for the application by means of small to medium-sized modifications.

Some examples:

- Units with temperature-resistant cover band (Valflon)

- Clean room versions (various classes)

- EX protection versions (in conformity with the ATEX guidelines)

- Stainless versions, units with compressed air connection

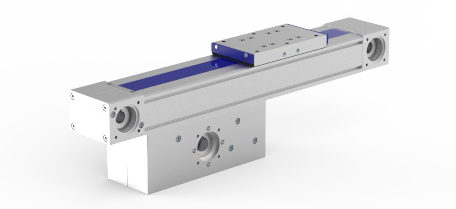

Multiple units

Individual drives are adhered to form a multiple unit. This results in double, triple, quadruple or even quintuple units. The individual profiles are either mounted on a common basic plate and partially adhered, or are just adhered together in a device.

The basis of most customised solutions in this field is formed by our HSB-beta® mechanical linear units. Multiple units with toothed belt drive or screw drive are possible, also in combination with guide units without drive.

In the field of screw drive units, we have already realised units with up to 10 independently-powered carriages. Linear units with dual screw drive are also used for this.

Multiple units

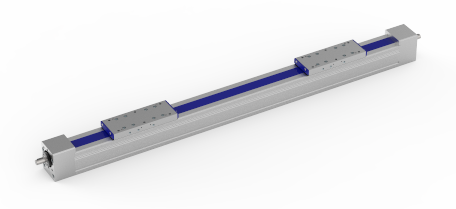

Linear units with dual screw drive

Almost every one of our linear units with screw drive can be provided with 2 screw drives, 2 fixed bearings (A and B) as well as 2 carriages that can be moved independently of one another. The movable bearing is then in the profile tube.

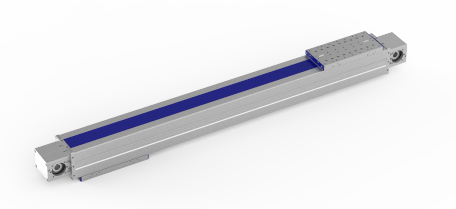

Double stroke units

In practice, it is often the case that a specific stroke is required but the given installation length is insufficient for a standard linear unit. Here, the solution may be a so-called double stroke unit.

This is essentially two units, the profiles of which are joined at the rear and the two opposed carriages of which are driven by a common toothed belt. The double stroke unit is a kind of simple telescopic unit.

Double stroke units

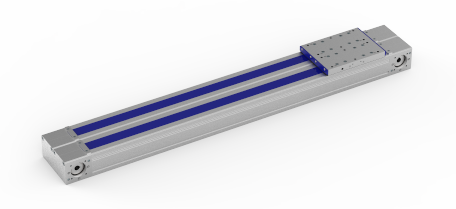

Units with 2 toothed belts

2 carriages can be moved independently of one another via 2 circulating toothed belts. Our HSB-Gamma®-ZSSD and HSB-Sigma®-ZRSD were developed from this version, which was originally conceived as a customised solution.

Toothed belt units with concentric/eccentric drive

In the case of applications where the drive motor cannot be mounted on the bearing housing of a classical toothed belt unit, under certain circumstances this version is the perfect solution.

The drive block with the Omega drive of the corresponding ARS/ASS version can be mounted on the underside of the profile and can serve as a drive.

Rotary feedthroughs

Rotary feedthroughs have been realised for various unit sizes of the HSB-beta® range as well as most sizes of the HSB-gamma® and HSB-sigma® portal linear units.

These are primarily used in vertical units where something must be turned (e.g. grippers) and the drive is desired at the upper end. The problem-free feedthrough of cables or hoses is also possible here.

Rotary feedthroughs

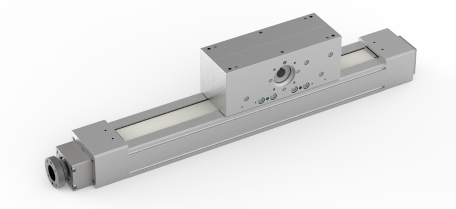

Heavy duty linear table

For certain areas of industrial automation, classical linear units and linear tables are insufficiently dimensioned due to their design. This can be the case with respect to the entire assembly, or in the area of the guides and/or the drive.

Among other things, HSB manufactures linear tables completely from steel, with dimensions attuned to the customer, e.g. with recirculating roller guides and special planetary roller screws.

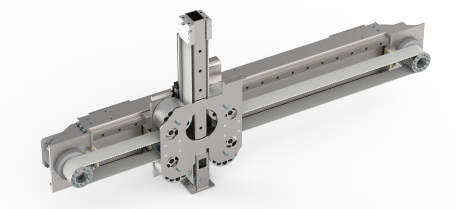

2-axis system with standing drives

In the case of highly-dynamic applications, it is always important to keep the moving mass as low as possible. We have been able to achieve this with our HSB-kappa® special unit.

HSB-kappa®